Sansyo produces firm and resilient noodles using our unique "8-stage preparation" method of rolling and the industry's first 22-hour long aging process.

Depending on the temperature and humidity at the time, water is added to the maximum extent possible for the final udon noodles. The best mixing time is 5 minutes, during which time the dough is allowed to become a batter. The five-minute mixing time is the result of our research and is the optimum kneading time for the right mixing of flour and water.

Please enable English sub on youtube.

Once mixing is completed, the next step is our unique two-stage long-time ripening process. Ripening is the process of letting the dough rest, and in the first stage, the dough is ripened at 28°C for 2 hours. In the first stage, the dough is aged for 2 hours at 28°C. At this time, we relieve the stress placed on the dough during mixing and allow the moisture to fully penetrate into the flour. This is the so-called “sleeping” process. It relieves the stress placed on the dough during mixing and allows the moisture to permeate the flour.

Sansyo’s unique “8-layer preparation” method. The dough is folded and pressed gently and forcefully to make 8 layers of dough, which gives the dough a firm, firm, and elastic texture.

Dough forged by pressing is subjected to a lot of stress.

Overnight aging at Sansho relieves this stress. This is an important process that protects the gluten structure and produces a delicious texture.

The overnight dough is gradually stretched so as not to destroy the gluten structure.

The thickness of the dough is a very important factor for good taste, and we pay close attention to even the slightest difference in thickness in our noodle making process.

The overnight dough is stretched in eight stages so as not to destroy the gluten structure.

The dough is stretched by inverting the dough to create a noodle line without losing texture.

After rolling, the dough is cut out in a cut width appropriate for the noodle type.

The thickness and width of the cut noodles are measured at regular intervals to ensure that they meet the standard values.

After rolling, the dough is cut with a large knife. Cutting with a knife gives the dough a sharper edge, which improves the texture and throat.

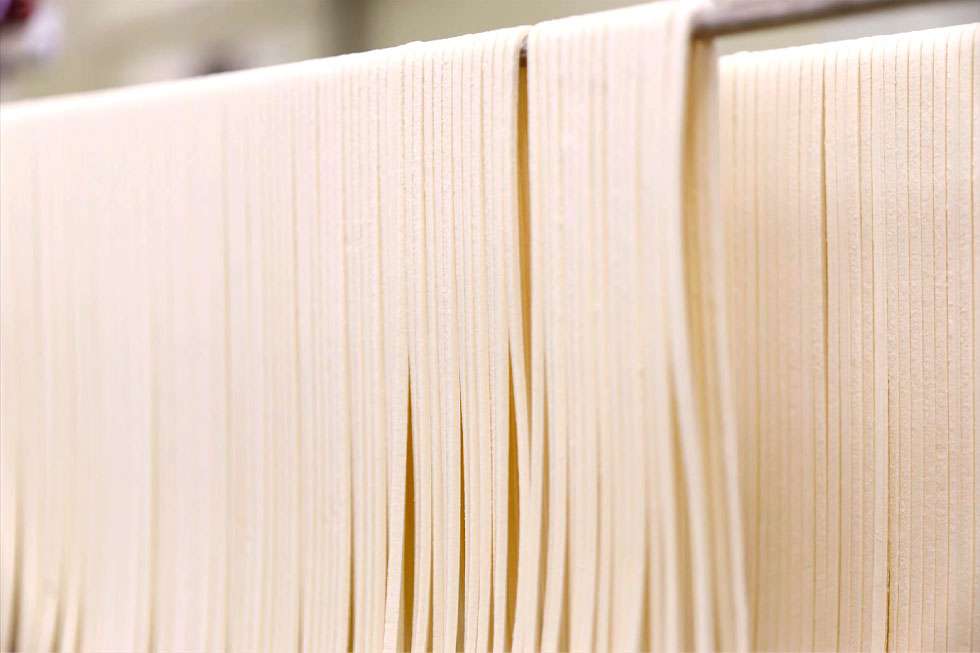

The cut noodles are hung on poles and dried overnight in a cold-air drying room with temperature and humidity controlled. San Takumi insists on “cold air drying,” even though it takes longer, to prevent the noodles from losing their freshness due to hot air drying.

Once the noodles have been cut, inspected, and packaged, they are immediately flash frozen. The noodles are frozen at -40°C to prevent ice crystals from destroying the gluten structure, and thus we are able to deliver noodles with firmness and consistency close to that of freshly pounded noodles.

The overnight dough is stretched in eight stages so as not to destroy the gluten structure.

The dough is stretched by inverting the dough to create a noodle line without losing texture.

In order to deliver noodles of consistent quality, we conduct detailed visual and numerical checks at each step of the process.

In addition, we conduct taste tests on all types of noodles every day and deliver only those that pass the taste test.